A decentralized point of sale (POS) warehouse strategy coupled with a lack of data-driven purchasing decisions was leading to runaway costs associated with the storage and management of POS marketing material.

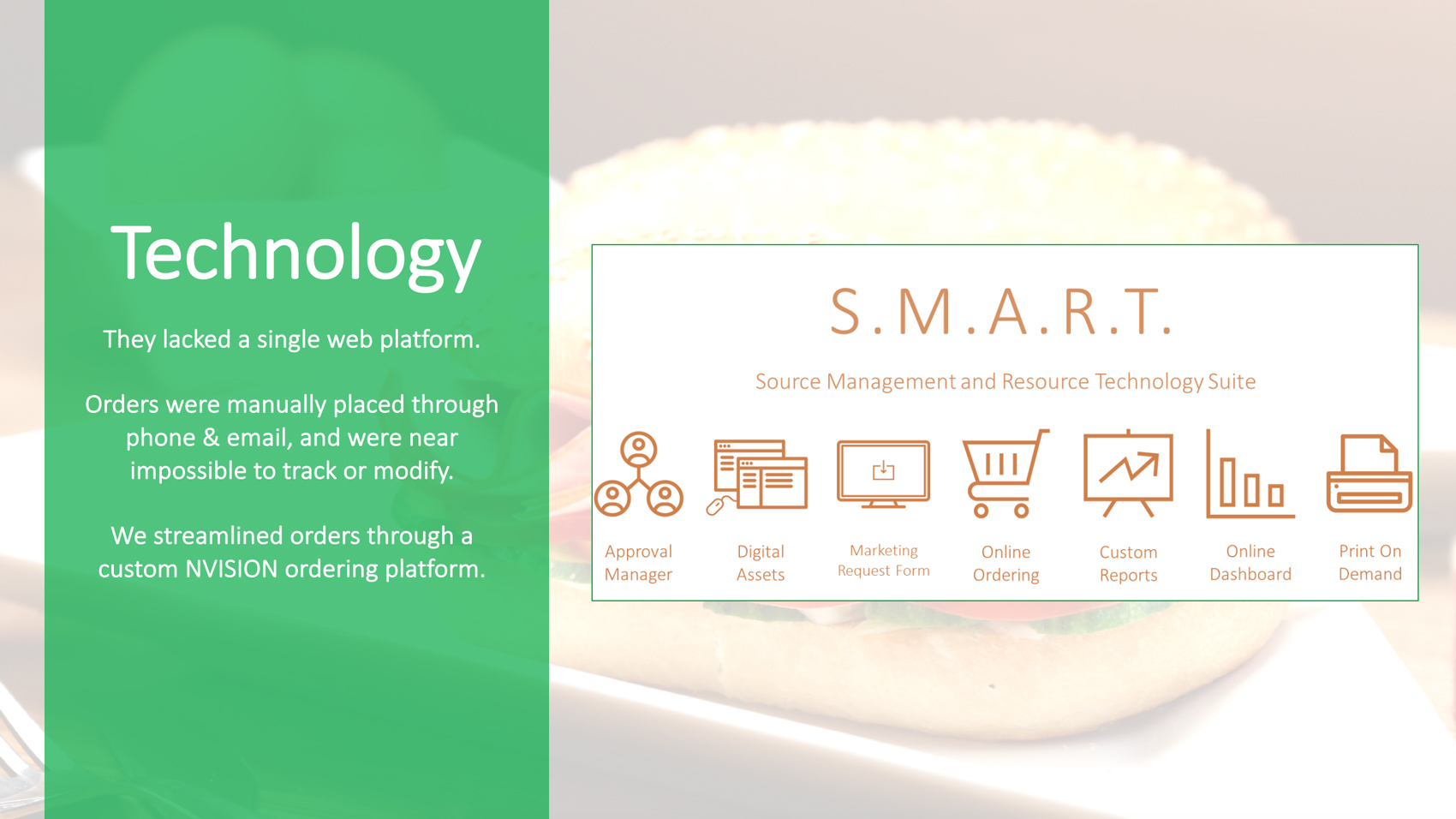

Complicating matters, the team in charge did not have the expertise, technology or experience to make the appropriate corrective measures.

Solution

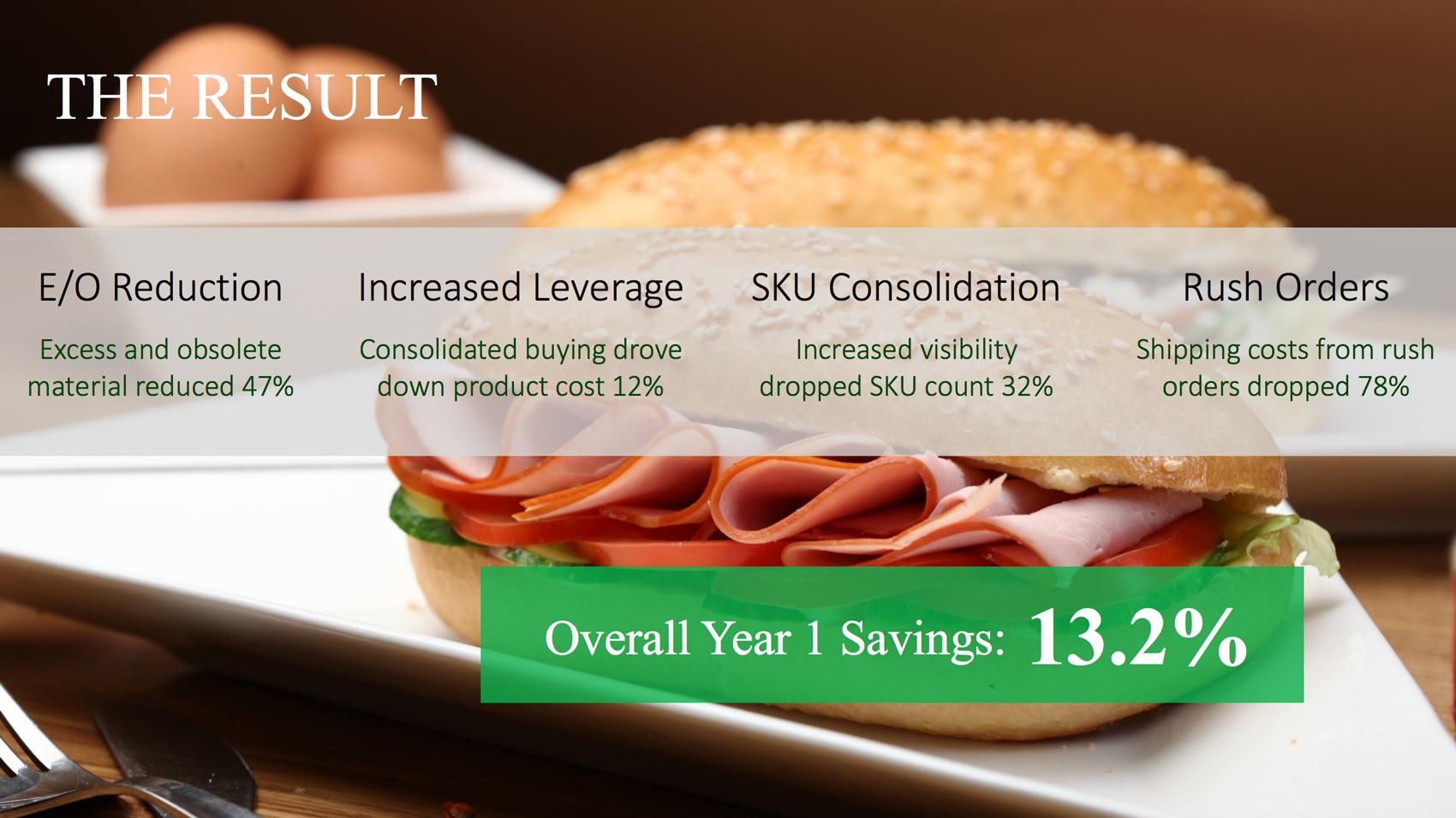

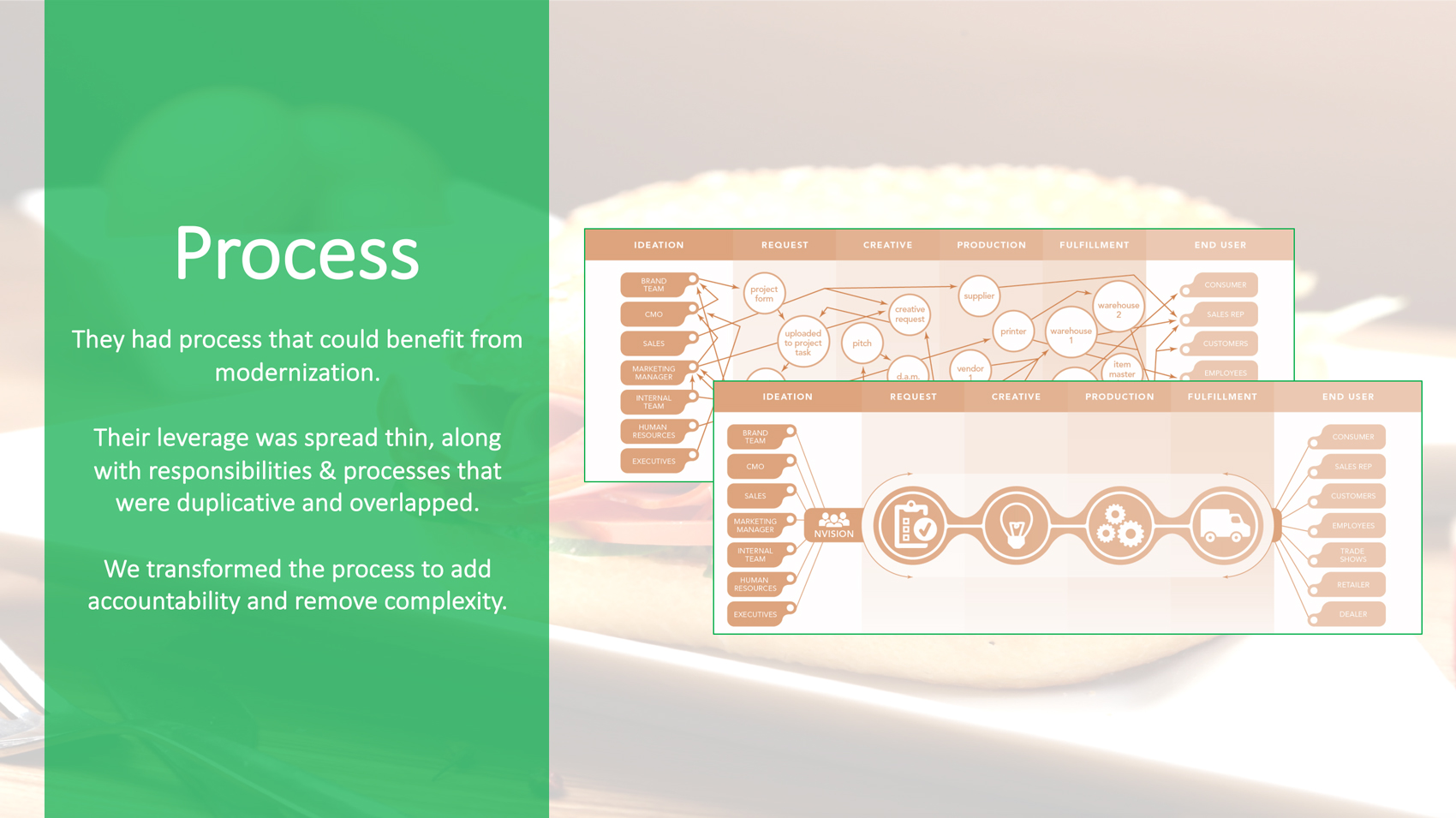

NVISION centralized warehousing and fulfillment, and tasked manufacturing plants to act as mini DC’s to the retailers. We also moved orders for POS marketing material to a centralized model where they would be bundled with the food and shipped together as a unit via a strategic geographic distributor network.

We consulted with the client’s manufacturing and marketing teams to design a strategy focused on budget, timing and ROI requirements. The result was a newly formed multi-bid process with procurement guidelines designed to streamline the process while achieving warehousing and freight savings targets.

Client

Leading food manufacturer

Project

A prospect came to us seeking help with warehousing, fulfillment & distribution for their:

- Displays (perm, semi-perm, temp)

- POS Material (tear pads, IRC Coupons, etc.)

- Branded Merchandise

- Apparel

What We Did

Assessed, implemented and managed a solution to streamline their warehousing, fulfillment & distribution needs.

Project Title

Project Title Project Title

Project Title